Shop drawings that are precise and accurate reduce, or even eliminate, fabrication or installation rework by resolving issues and clashes early on. As a result, unnecessarily high labor and material costs are avoided.

What are Shop Drawings?

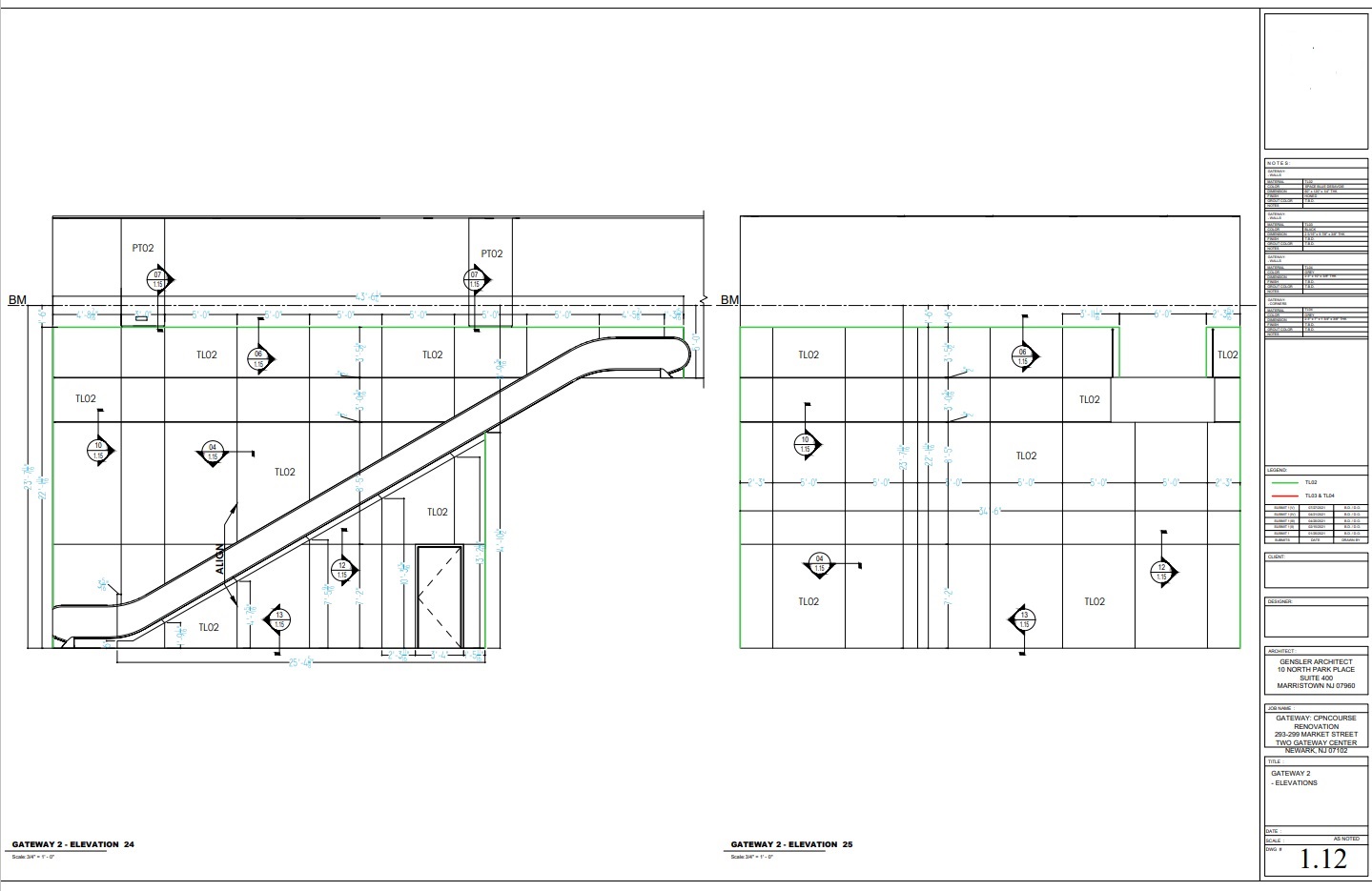

Detailed plans that convey design intent are known as shop drawings. They are the manufacturer’s or the contractor’s version of information shown in the construction documents. Shop Drawings explain the fabrication and/or installation of the items to the manufacturer’s production crew or contractor’s installation crews.

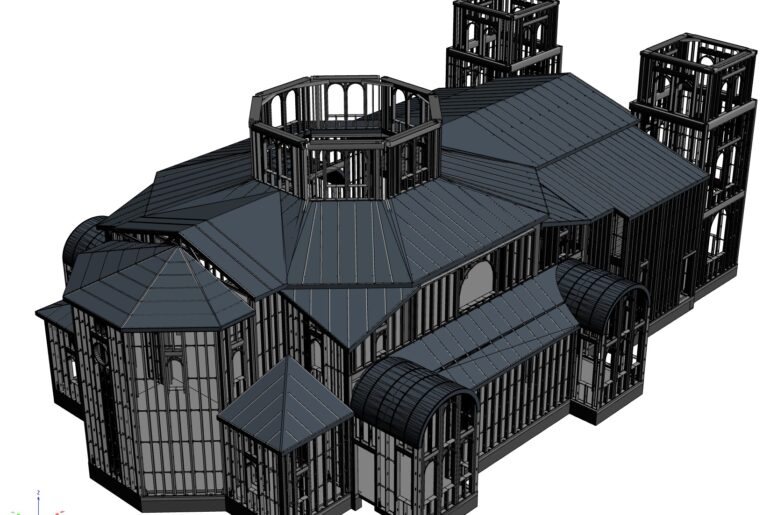

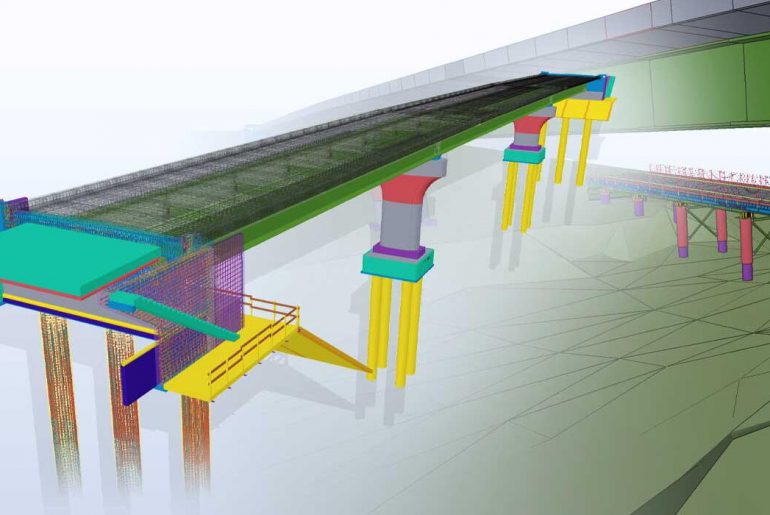

The design intent for the installation of Marble Wall Tiles is seen on the left in the image above (image by Gensler) The figure to the right illustrates Shop Drawings’ interpretation (image by iDRAWPRO.com) of the construction documents, including layouts, dimensions, and material information.

Installers and fabricators are required to provide shop drawings in general. They usually contain the following details:

- Dimensions and particular materials to be used.

- Information about installation means and methods.

- Dimensions, layouts that must be verified on-site

- References to the construction documents in order for the architect or engineer to sign off.

- Notes on changes to the construction documents

- Materials, hardware and surfaces to be used.

The Importance of Quality Shop Drawings

Shop drawings that are precise and accurate are crucial and can help :

- Ensure that the architect or designer, the client, and the fabricator are all on the same page.

- Provide enough information to the fabricator to guarantee that elements are structurally sound and meet all safety, quality, and project standards.

- Reduce, or even eliminate, fabrication or installation rework by resolving issues and clashes early on. As a result, unnecessarily high labor and material costs are avoided.

Conclusion

While it is understood that the time spent developing, evaluating, and eventually approving shop drawings can affect a project’s overall timeline, the losses caused by the construction of elements contained in inaccurate shop drawings are frequently significant. As a result, the project could be delayed, and the cost of fixing the problem could increase.

When shop drawings are required, it is absolutely crucial to first find quality shop drawings provider and second to make sure they are reviewed, checked and approved by the design professional.