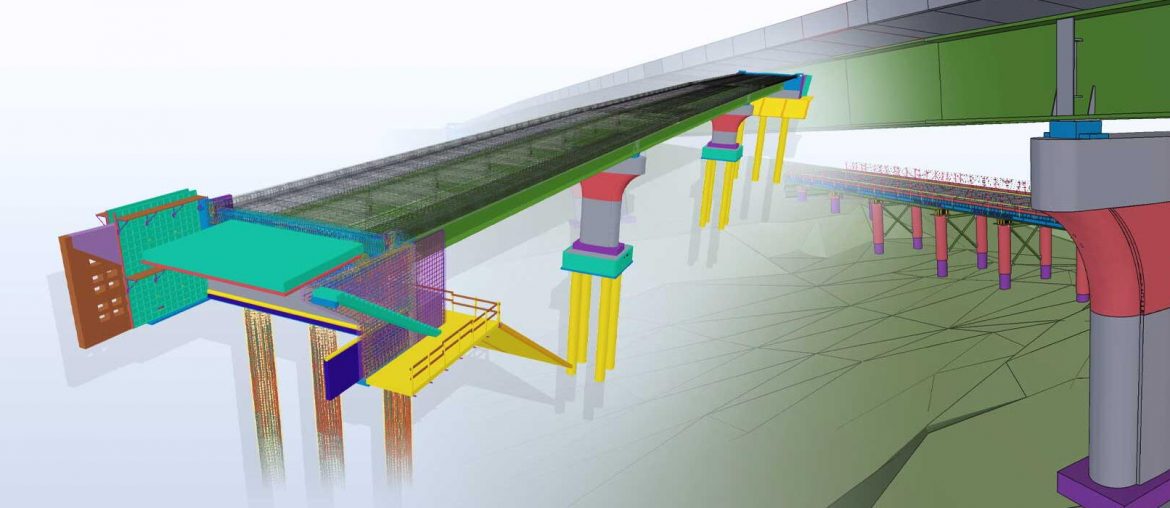

Our structural shop drawings come with the included interactive virtual 3D model. Rotate, spin, zoom, turn elements on and off. Opens with a free pdf software and is free.

How it works

Our shop drawings are made with the leading software and latest technology which allows us to provide an option to generate a virtual 3D model which exactly reflects the 2D shop drawings.

The 3D model comes with each order as a pdf file which can be opened with a common and free software like Adobe Acrobat Reader or Bluebeam Revu.

Video 1 above shows the 3D model opened with a free Adobe software. The model rotates by moving mouse in the desired direction while holding the left mouse button. The layers like steel beams or columns can be turned on or off in the left toolkit.

Video 2 below shows 3D model from the same project but this time for concreter and rebar placement for footings and slab. IDRAWPRO.COM provides shop drawings for all construction trades with available 3D model.

We can see the same operation including rotating, zooming, hiding different elements like steel beams, masonry walls etc.

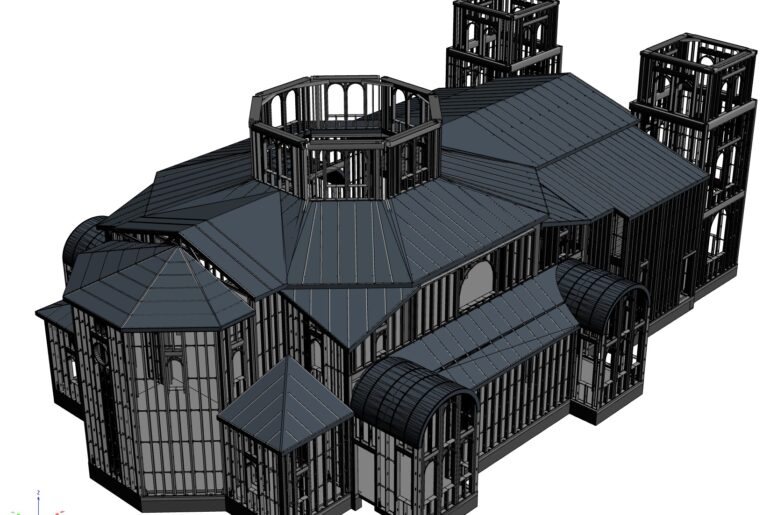

Video 3 above shows another 3D model from different project. This 3D model is generated from the floor joists shop drawings. We can see the same operations including rotating, zooming, hiding different elements like steel beams, masonry walls etc.

It is important to mention that the 3D model reflects the 2D shop drawings exactly, with all dimensions, sizes, scale and material types. Thus, providing a very useful tool for clash detection and resolution.

Avoid costly mistakes.

The use of latest technology allows for accurate translation of the design concept from the project drawings into reality. All the components of the structure are displayed in their full geometries instead of only showing confusing and overlapping lines. As a result, the installers get the real picture of what goes where and how. Additionally, any clashes with neighboring elements are identified much earlier in the process, and viable solutions can be found before ordering materials. This translates into direct savings in time, materials, and resources on-site and benefits all parties involved in the construction process including the design team, fabricators and installers.

IDRAWPRO.COM provides the following structural shop drawings with the included interactive 3D model; Structural Steel, Rebars, Joists, Ornamental Steel, Railings, Stairs, Fences

Visit our website IDRAWPRO.COM for more information and to order our servies.