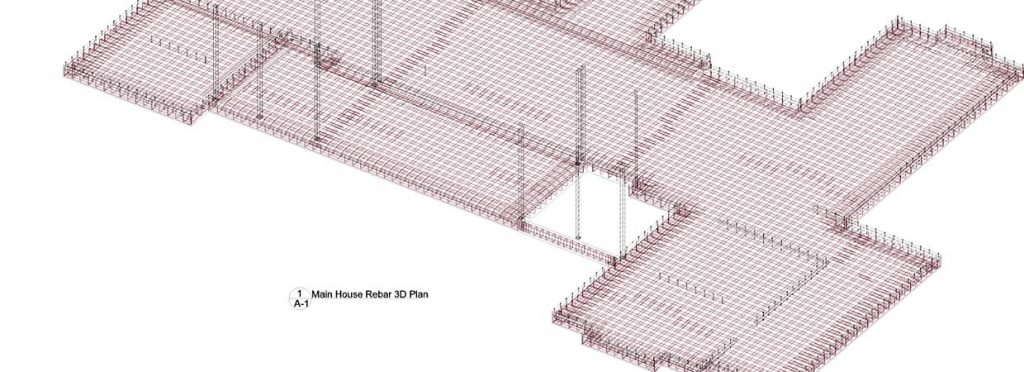

With 3D enhanced rebar shop drawings, concrete placing contractors can resolve 90 percent of problems before the start of construction, reducing operational and material costs.

The new approach

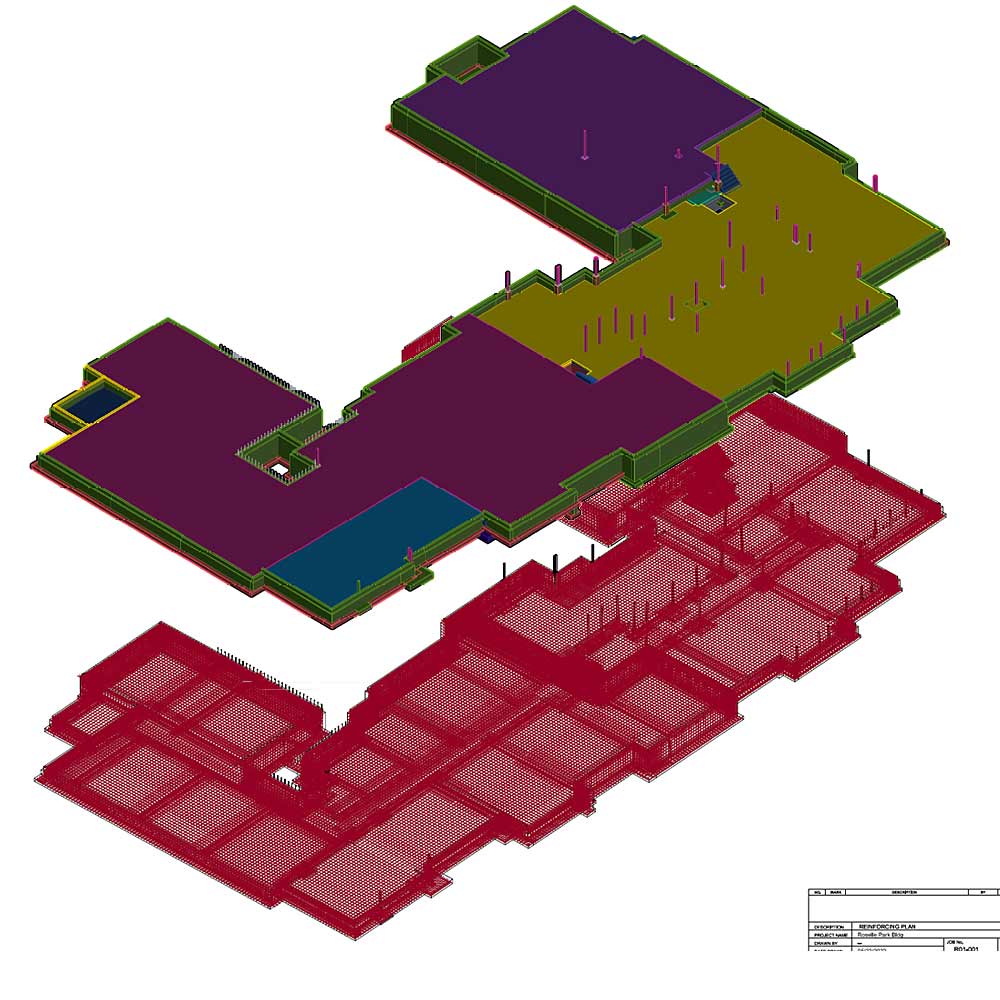

The software used by rebar detailing companies like iDRAWPRO accurately translates the design concept from the project drawings into reality. The reinforcements and concrete are displayed in their full geometries instead of only showing confusing and overlapping lines. As a result, rebar placers get the real picture of what goes where and how. Additionally, any clashes with neighboring elements are identified much earlier in the process, and viable solutions can be found before ordering the bars. This translates into direct savings in time, materials, and resources on-site and benefits all parties involved in construction including the design team, fabricators and installers.

Unexpected benefits

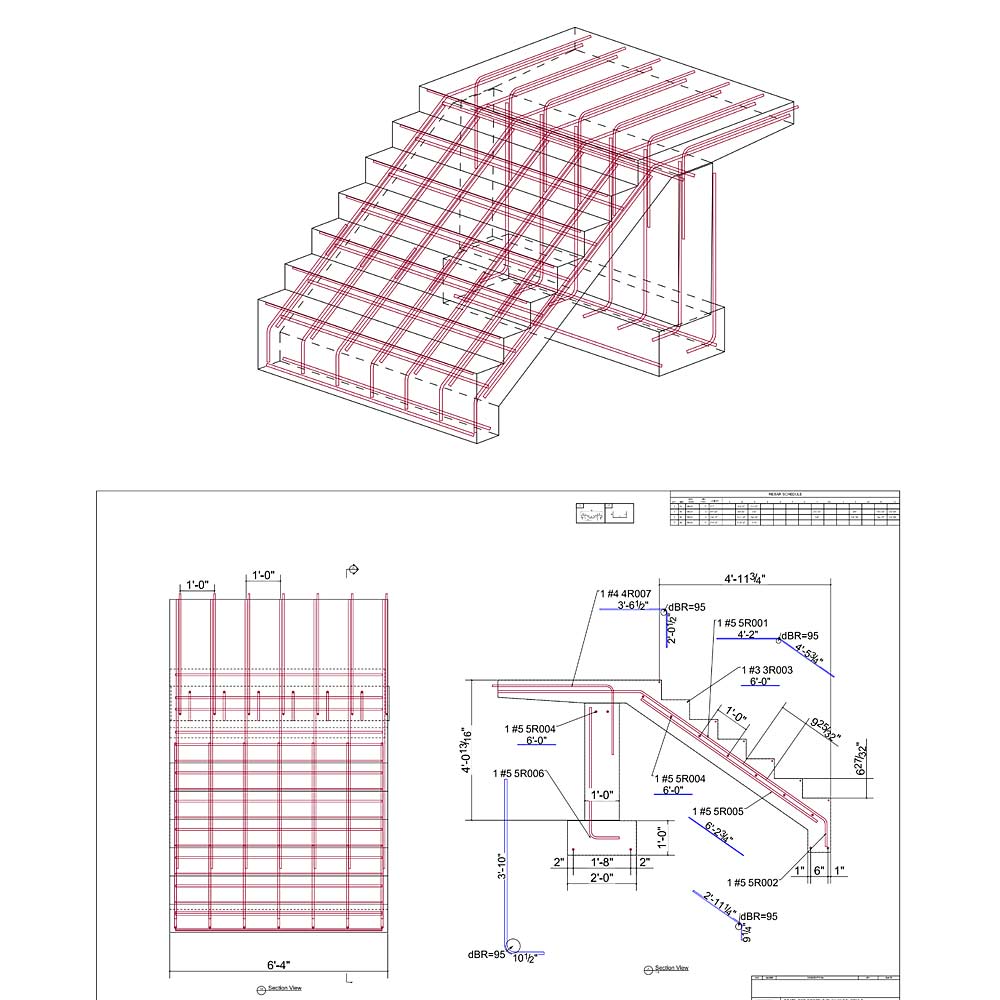

Another advantage of this new approach to rebar detailing is the ability to zoom drawings to the smallest detail with the use of everyday devices like smartphones or tablets, eliminating the need for large format prints and thus helping the environment.

3D drawings allow rebar placers to zoom to the smallest details on the shop drawings to see how to place the rebar in the designated areas.

Even more advantages

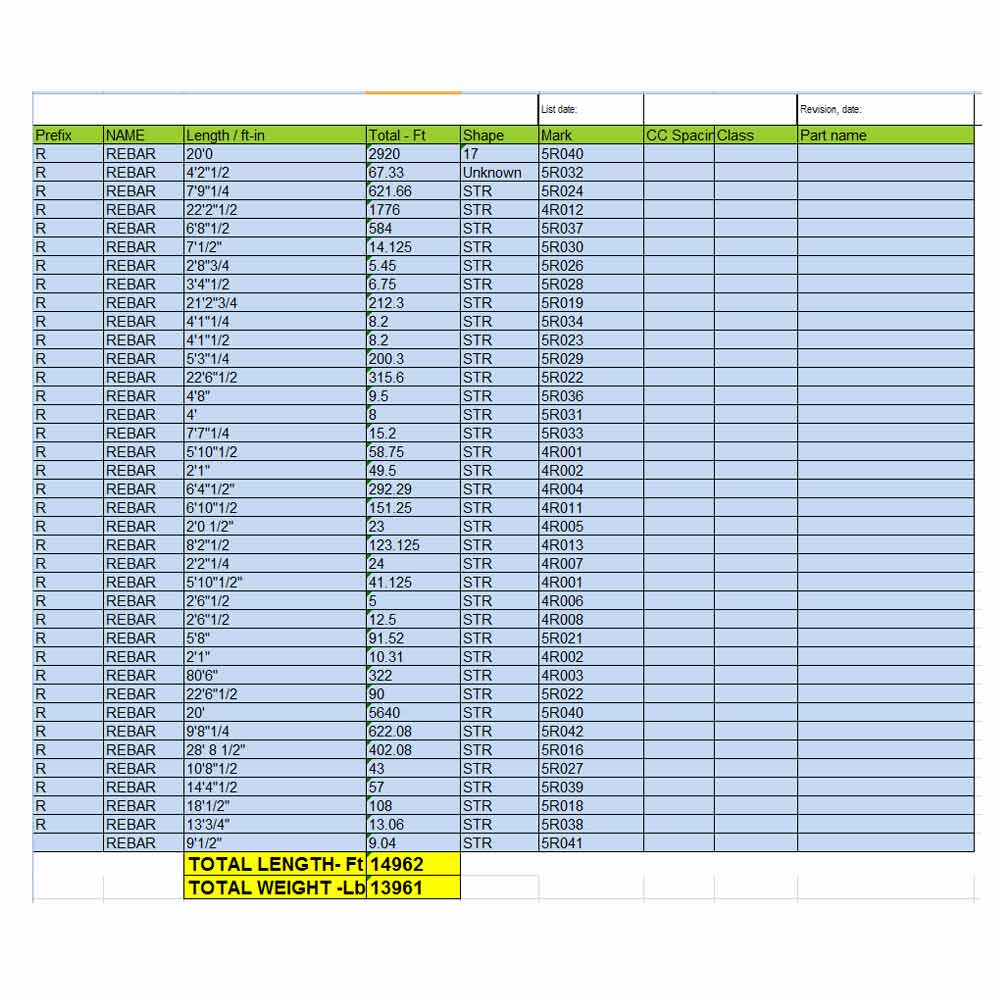

All the information entered during shop drawings preparation can be easily extracted in a form of an Excel table with rebar data such as lengths, sizes, quantities and weights. All this data can then be used for takeoffs and estimating tools minimizing the risk of blowing an estimate based on miscalculated quantities.

Examples

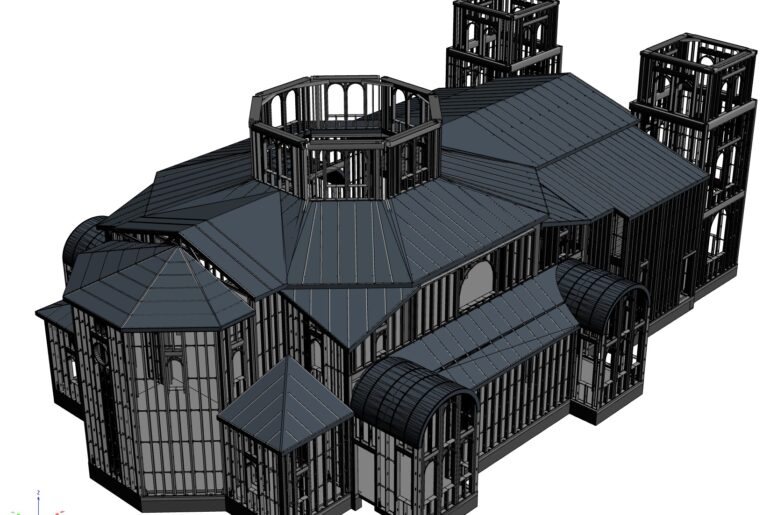

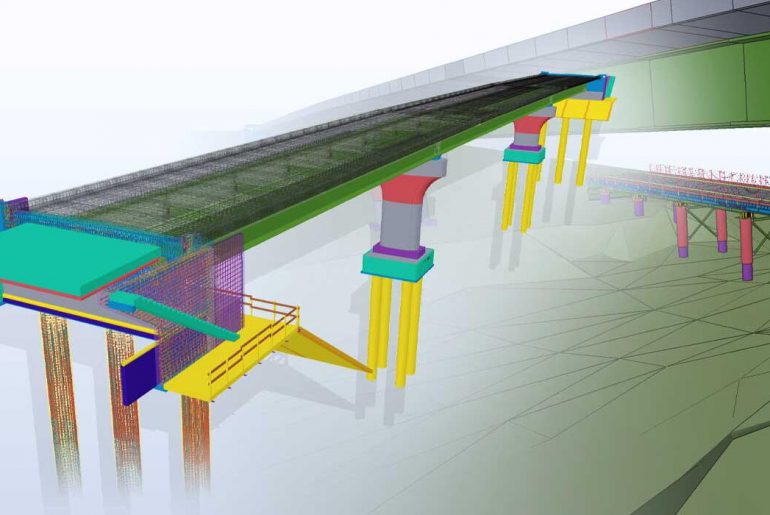

View the examples of completed rebar detailing projects with optional 3D drawings.