The development of precise drawings for steel fabricators and steel erectors to use in the construction of buildings, bridges, and other structures is known as structural steel detailing. Steel detailers provide detailed designs, drawings, and material reports for the fabrication and installation of steel columns, beams, braces, trusses, girders, and other miscellaneous steel such as stairways and railings.

The importance of steel detailing

Today’s projects frequently begin with a sketch on a napkin and swiftly go to groundbreaking and foundation pours before the owner’s and architect’s visions have been thoroughly evaluated and coordinated across all trades.

Thankfully, steel detailing companies like iDRAWPRO.com ease the process by assisting contractors, architects, and engineers in realizing their objectives through experience and innovation.

Efficiency through innovation

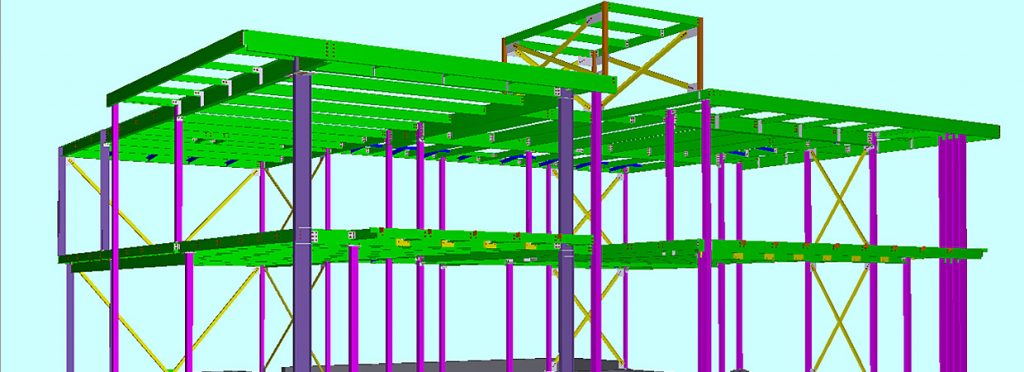

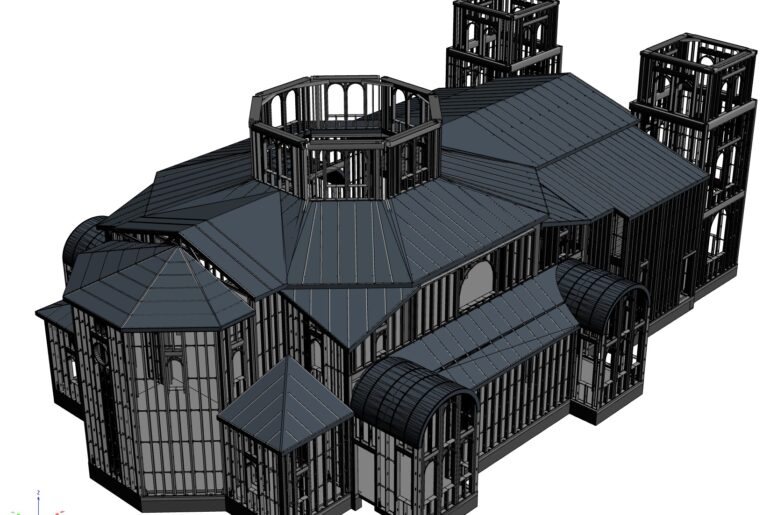

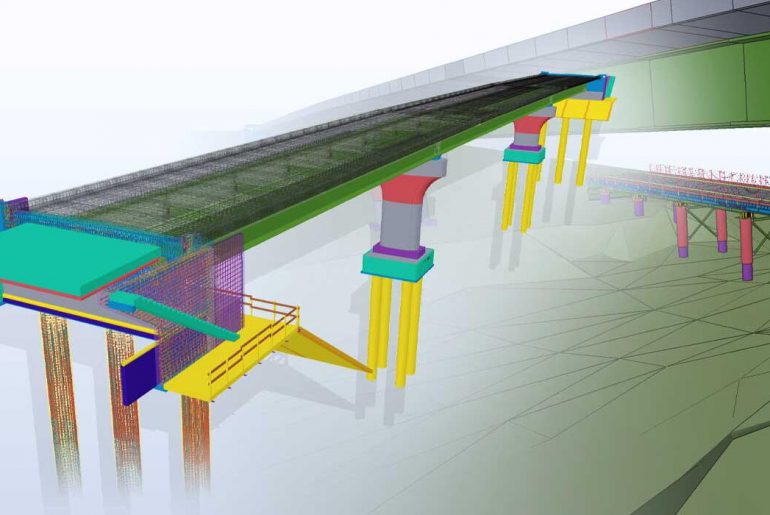

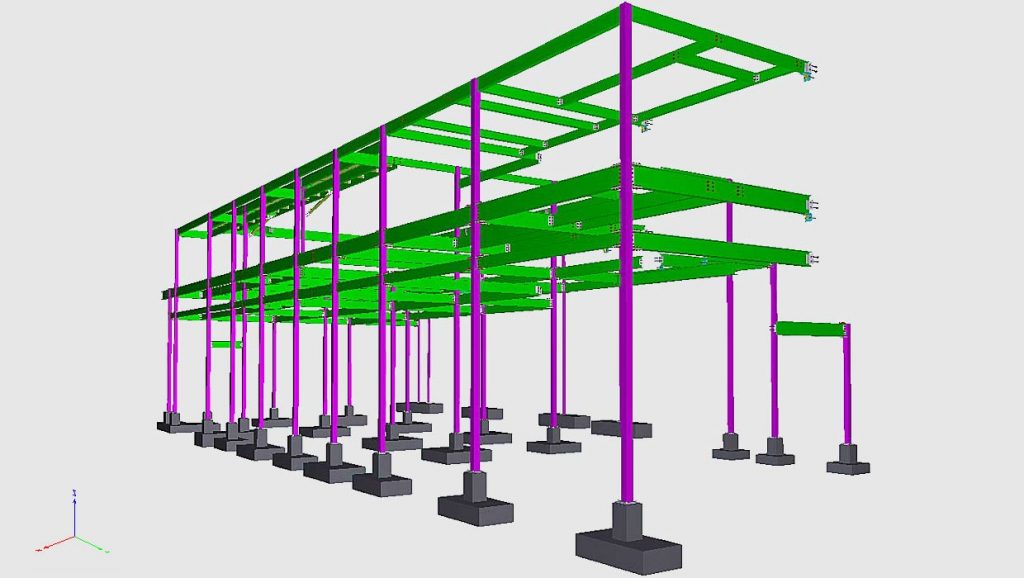

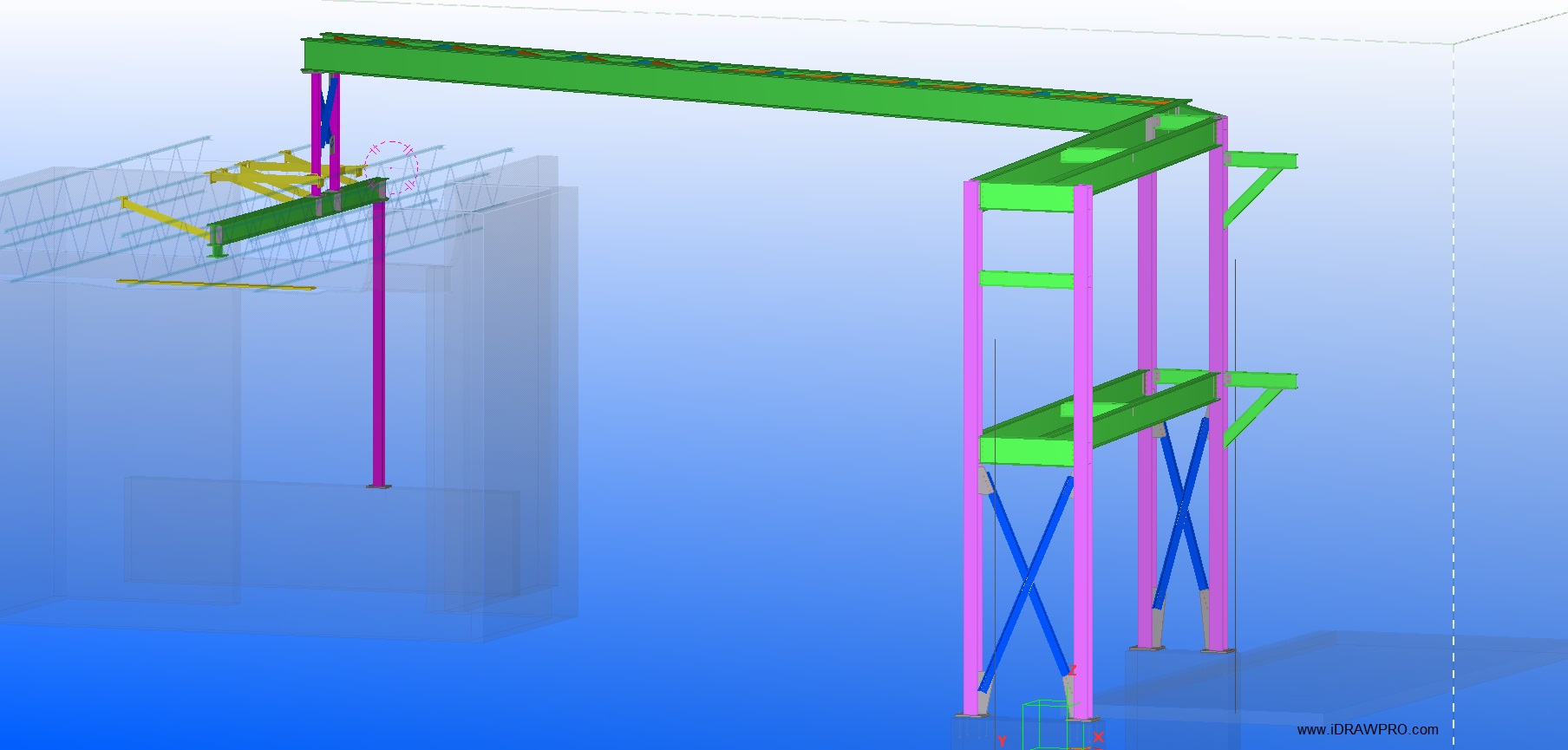

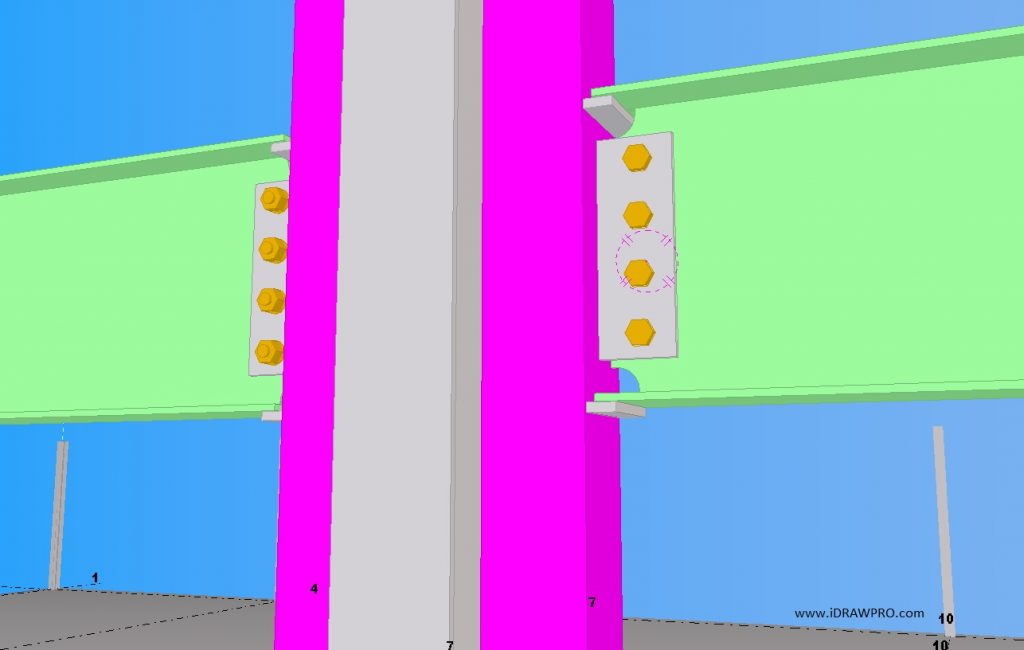

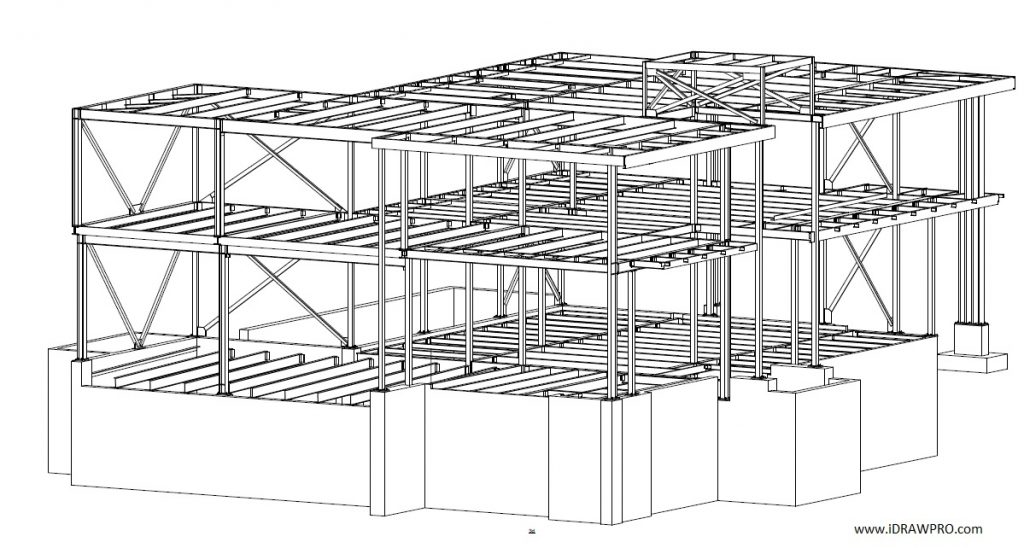

Modern techniques, such as leading steel detailing software, enable the creation of an interactive virtual reality that accurately reflects project blueprints. All steel members and connections, including dimensions and sizes, are presented exactly as they will appear in reality after the input of data from project drawings and specifications. The entire 3D model of the steel structure can then be exported to other software, which is often used by architects to coordinate the other trades.

With a virtual reality tool like this, experienced detailers may quickly spot possible issues and notify the design team before fabrication, reducing rework costs.

What should be included

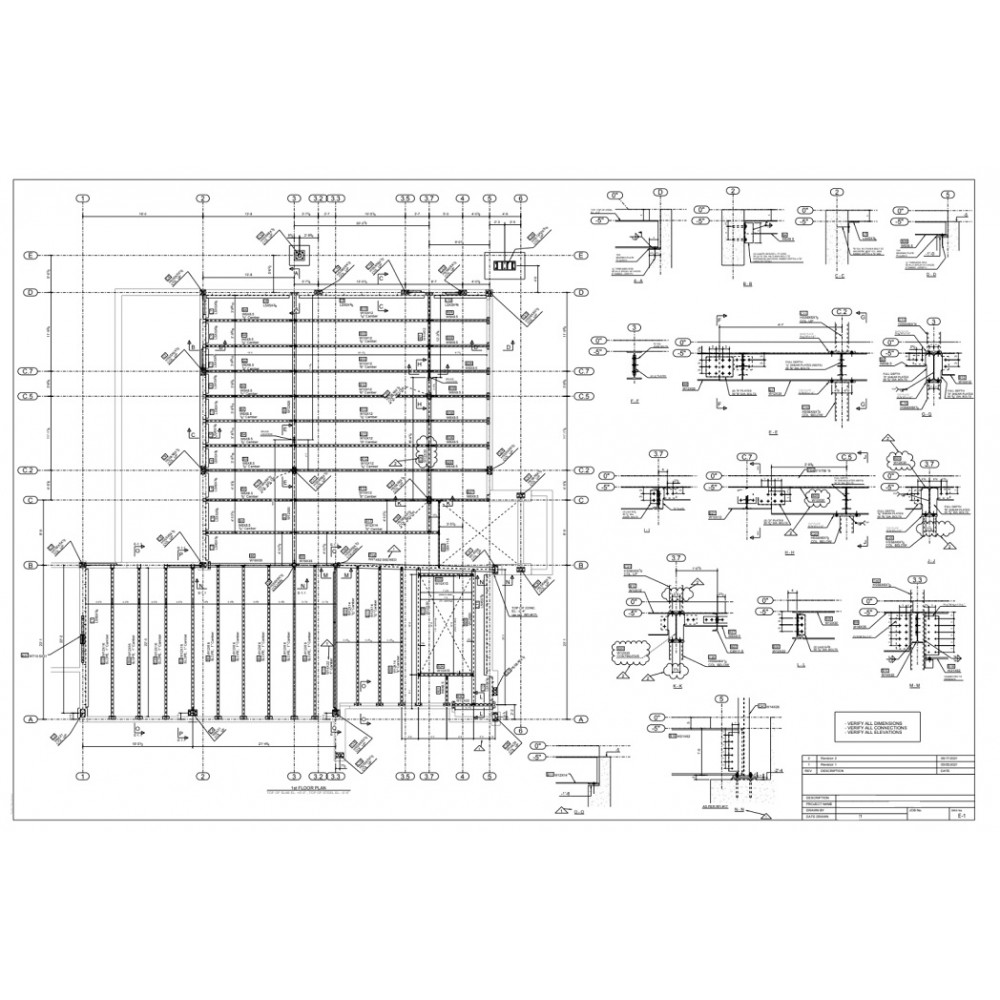

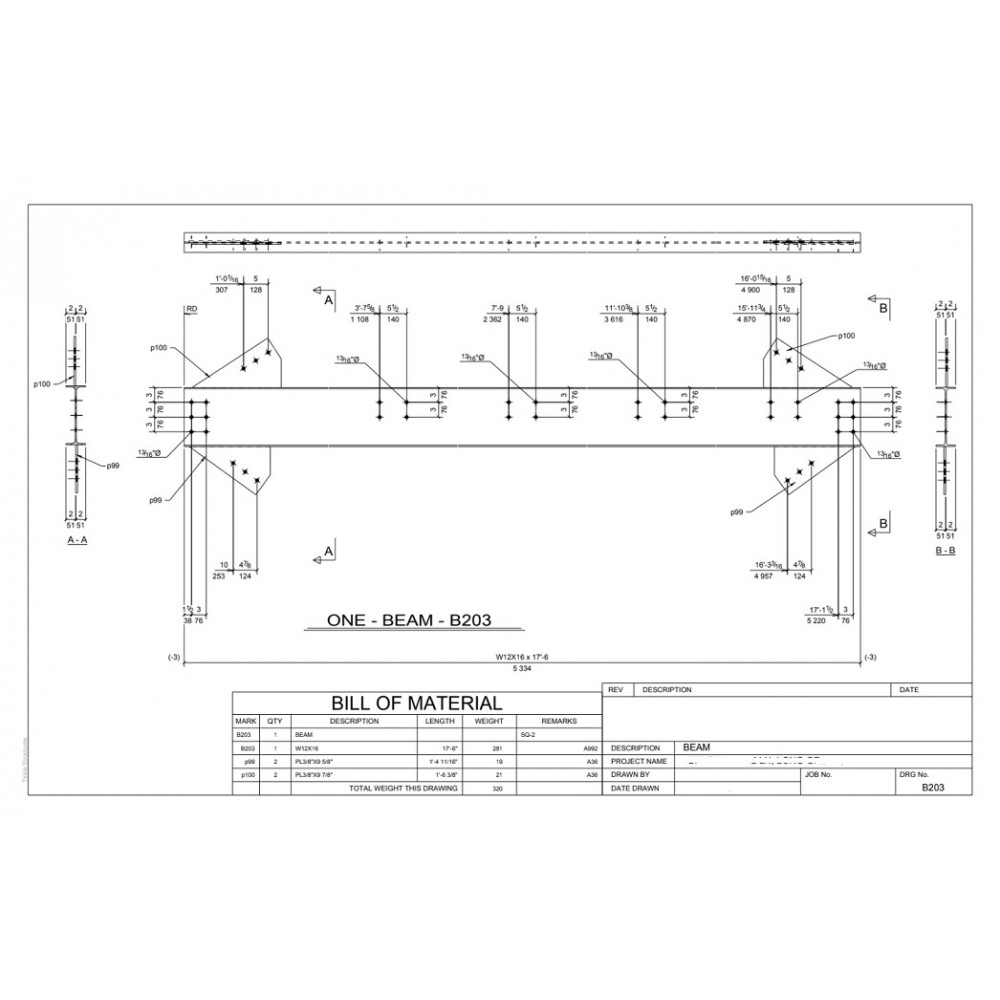

The full package of quality structural steel shop drawings should include:

- Erection and fabrication drawings,

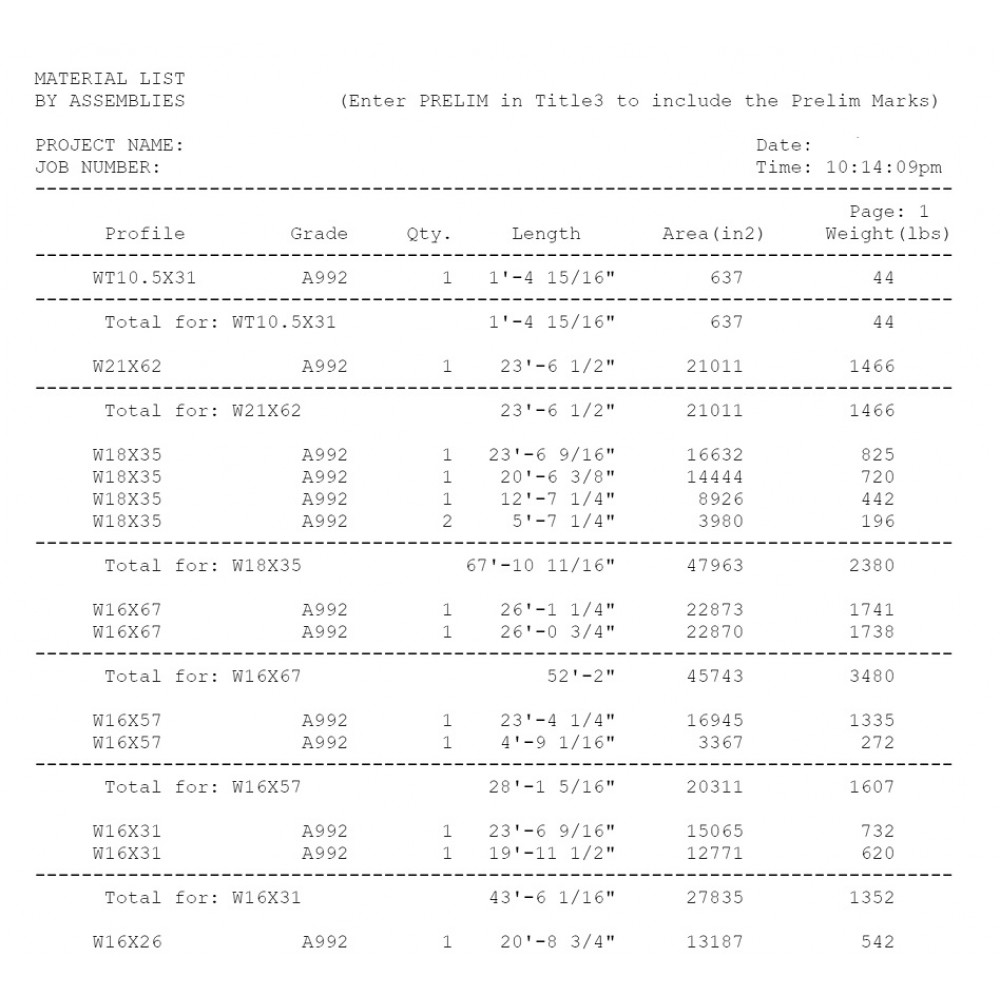

- Bill of Material,

- 3D model and CNC data for fabricator

- 3D model for the design team

- Reports containing the list of parts with weight for estimating

- Mechanical and Epoxy Anchor Bolt and Fasteners List

Choosing the trusted services

Reliable shop drawings services reduce, or even eliminate, fabrication or installation rework by resolving issues and clashes early on. As a result, unnecessarily high labor and material costs are avoided.

Examples

View the examples of completed structural steel detailing projects with optional 3D drawings.